Main Technial Parameter of CE,ISO,SGS gray board machine manufacturer cardboard tube craft paper making machine |

||||||

Main Technical Parameter |

1 |

Raw Material |

waste paper,recycled paper,virgin pulp |

|||

2 |

Output paper |

high quality kraft paper,fluting paper,corrugated paper,liner paper |

||||

3 |

Production |

30ton/day(24hours) |

||||

4 |

Paper weight |

100-300g/㎡(can be adjusted) |

||||

5 |

Net paper width |

2100mm |

||||

6 |

Width of cylinder mould |

2600mm |

||||

7 |

Rail Guage |

3000mm |

||||

8 |

Design Speed |

100m/min |

||||

9 |

Work speed |

33-99m/min |

||||

Main structure of Paper making machine of CE,ISO,SGS gray board machine manufacturer cardboard tube craft paper making machine |

||||||

1.Wire part |

Cylinder mould :Ф1500mm 3 sets,material :cast iron ,Stainless steel plate ; Couch roll: Ф400mm 3sets,coated by rubber,rubber shore hardness 38℃±2;

Turnround roller:Ф450mm 1set.ordinary steel+90°rubber+45°round steel.

|

|||||

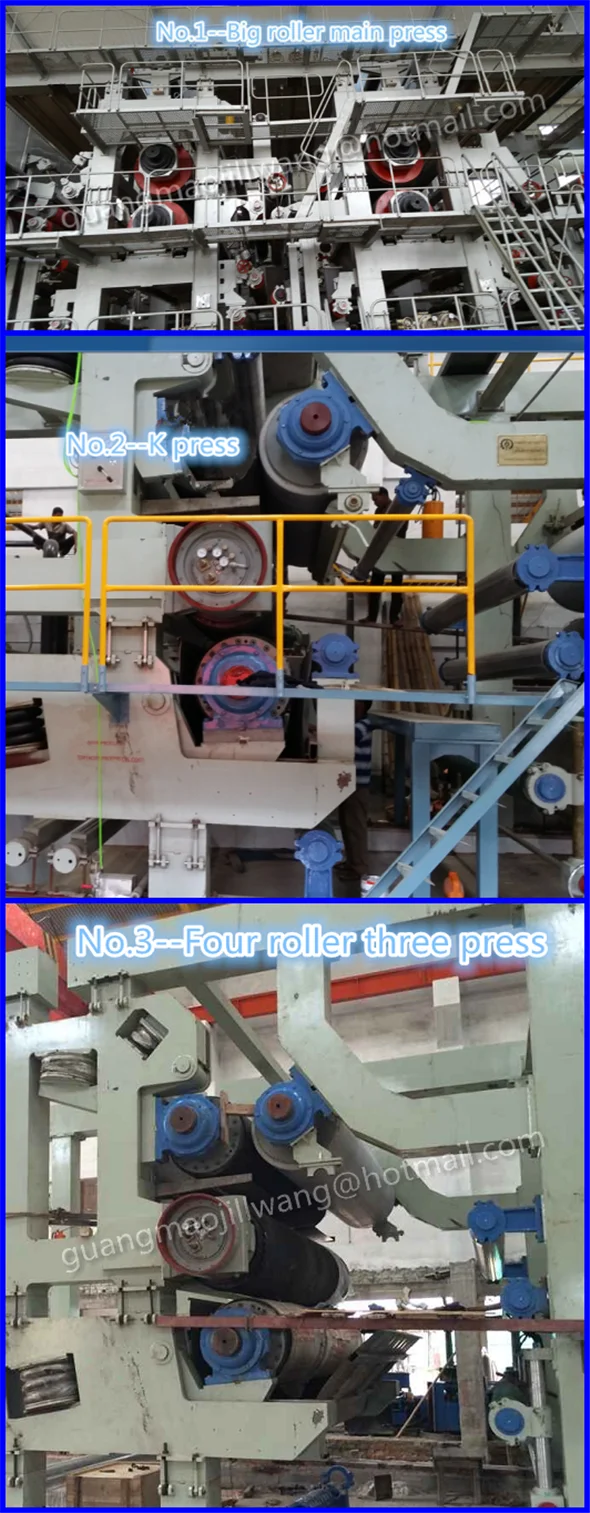

2.Press part |

There are total three groups of press, 1st press group is K press,it include 1set marble roller with size ɸ850mm,1set vacuum roller with size ɸ800mm,1set rubber roller with size ɸ750mm,pneumatic loaded device;2nd press is main press,it include 1 set marble roller with size ɸ850mm,and 1 set rubber roll with size ɸ800mm,pneumatic loaded device; |

|||||

3.Dryer part

|

It is consist of 12sets of ɸ1500mm dryer can, the bearing of dryer can is antifriction bearing, gearwheel transmission. |

|||||

4.Sizing machine |

Two roller sizing machine,1set.It include 2 rollers,both of the roller size is ɸ550mm. |

|||||

5.Calender machine |

This calender include 2rollers,upper roller is ɸ450mm,below roller is ɸ500mm,cast steel chroming. |

|||||

6.Reeling machine |

level type reeling machine, 1 set,Reeling machine is ɸ900mm(cast iron),max reeling diameter is: ɸ2000mm. |

|||||

7.Mechanical transmission |

Using AC frequency converter, drive part by part, each part is consist of 1 set of AC frequency motor, 1 set of gear reducer, 1 pc of universal shaft connecting shaft, 2 sets of coupling and 2 pcs of basic board. |

|||||

1. chain plate conveyor 1set

2. 10m³hydrapulper 1set

3. 850 thruster 9 sets

4. ZDF3 fiber separator 1 set

5. GM2 vibrating screen 1 set

6. 450 double disc refiner 1set

7. middle consistency pressure screen 1 set

8. 0.6 pressure screen 1 set

9. low consistency sand remover 3 sets

10. high consistency sand remover 1 set

11. pulp pump 12 sets

12. thickner screen 3 sets

13. pulp concentration control 1 full set

equipment

14. multi-stage pump 2 sets

Usually,it has two kinds of wire part,one is cylinder mould wire type,the other is fourdrinier wire type.Its function is to dewater from the wet paper.

It include several group dryers,the dryer size can be φ1800mm or φ1500mm. Their function is to make paper dry,after the paper come out from the dryer,the dryness can be 92%-95%.

Sizing machine's funtion is to add the starch to paper and let paper is waterproof.

Its function is to let the paper surface smooth.

Its function is to reel the paper into jumbo paper roll.

Its function is slit and rewind the jumbo roll into smaller width and diameter paper roll.

A.Pre-sale service

1.24 hours phone,email,tradem anager online services;

1.supply the detailed project report,detailed general drawing,detailed flow process design,detailed layout factory drawing for you until meet your requirement;

3.welcome you to come to our paper making machine factory and paper mill factory to have a look and check;

4.tell you all the necessary cost when set up a paper mill factory;

5.answer you all the questions within 24hours;

6.send you various quality paper samples made by our paper machine for free;

7.supply turn key-project service.

B.On-purchase service:

1.accompany you to check all the equipments made by us,and help you to make the plan of installation;

2.supply paper machine assembly drawing, the foundation and foundation load diagram, transmission diagram,formal installation drawing, use and installation instructions and a full set of technical data after signing the contract.

C.After-sales service:

1.delivery the machine as soon as possible according to your requirement,within 30days;

2.send rich practiced experience engineers to you to install and test the machine and train your worker for free;

3.give you one year guarantee time after the machine can run well;

4.After one year,we can guide and help you to maintain the machines;

5.every 2 years,we can help to overhaul the complete machines for free;

6.send you spare part in lower price.

Installation of CE,ISO,SGS gray board machine manufacturer cardboard tube craft paper making machine

We will send most professional engineers to install and test the machine for you until the machine can work well,these engineers are all have rich practiced experience in installing and operating the machine. After finish installing the machine,our engineers will train your workers,teach you paper prodcution technology,and teach you how to operate and maintain the machine. Our engineers can also stay in your factory to work long time for you.

We will also send you the necessary installation tools,pipe,valve,cable,flange,elbow and fitting,etc.

Products will be packaged according to their shapes, weight, transport distance and transport modes.large machines will be packaged in sections. every part of export machinery will be in standard export package seaworthy wooden case, waterproof film, straw rope, carton box,wood board,plastic foam, etc., which will ensure the intactness of products.

1.Why we choose your machine?

--we are guangmao machinery,a famous brand in China,a direct manufacturer with 34 years rich practice experience,golden supplier in alibaba for 7years.we can promise you high quality,lower price machine and best service;

--we have one professional technician team of 116 engineers and 12 experts and one innovative research team,always following advanced technology of Europe,so we can give you latest design;

--we strictly manufacture our machine according to international standard,such as ISO,SGS,CE,etc,our machine quality is good.

--we can supply you best after-sale service,we have a skilled and careful installation team,after you buy our machine,we will send most professional engineers to install and test the machine for you and also train your workers,teach them paper machine technology and how to operate and maintain the machine.So you no need worry.

--we can delivery in fast speed.

2.Can you make paper mill design for us?

--yes,but please tell us the size and shape of your land or workshop,we can make a detailed factory layout drawing accordingly.

3.Your machine price is high,is there any discount?

--our machine price is reasonable,we are factory,so machine price is factory price,we are signle-hearted to cooperate with you,we can give you some discount,but you should know,one quality,one price.

4.How can we visit your factory and what is the procedure?

A.our company located in zhengzhou city, henan province, it need about 2 hours from guangzhou city,1.5hours from shanghai city and 1 hour from beijing city by plane.we will pick you up at airport as well as the train station.

B.When you come,you can:

--check our manufacturing ability;

--check our workshop and faclities:

--check our running paper production line;

--discuss with our chief engineer face to face,we will solve all of your queries;

5. Your engineer can teach and train our worker and stay in our factory for long time?

--yes,of course,it is our service scope.

6.Can you ensure the high quality?

--yes, we shall inspect the equipment and issue the works Quality Certificate as well as the Product Inspection Report.

7.Can you accept turn-key project and OEM?

--yes.

8.I want to set up a paper mill,but I do not know how to start,can you help me?

--yes,friend,we have much practiced experience and already help lots of clients to set up paper mill,now their paper machine runs well and also make big profit.Contact with me,let me tell you more.

Our friendly team would love to hear from you!