Toilet Tissue paper Machinery: Softness That Lasts

Quality and going green are becoming major considerations in everyday items as solar-powered high technology comes into play in this day and age. Bathroom toilet paper, which is used every day, is no exception. The transitional period in areas of softness and durability is far from over; it is evident why toilet tissue paper machinery is essential in creating high quality products. This article will analyze the toilet tissue paper machinery, how it works in terms of innovation, how it manages to be soft and last through meeting consumer’s needs, and how effective its production is.

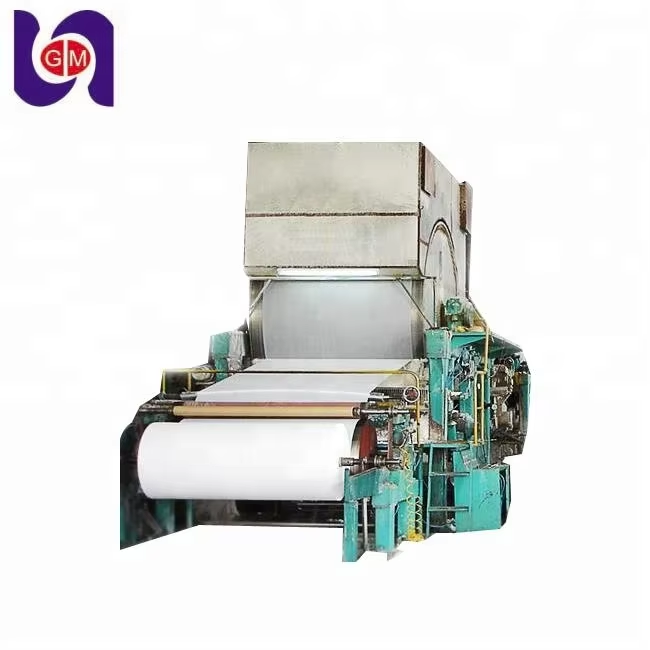

The Components of Bathroom Tissue Making Machine

Toilet tissue paper machinery functions as an equipment that creates drying and soft absorbing toilet paper rolls, able to do this by changing virgin fiber or recycled paper. Pulping, refining, pressing, drying and rewinding are some of the processes that the machine has to go through in order to create the actual product. High precision control and modern automation are examples of new technologies that were incorporated in the machines to diversify and reduce rolls to optimizing energy and minimization of required materials consumption during manufacturing.

How Technology Enhances Softness and Durability

With the advancement of technology, it permits so many things to be done with ease. One of the crucial aspects of paper toilet tissue paper machinery is the ability to engineer a container for two important properties, softness in combination with durability of the paper. Due to cutting-edge technologies, softness is imparted to the paper without affecting the strength or absorbency of the paper. This is done through different refining processes which help position the fibers in a manner that adds some texture while not disturbing the uniformity of the tissue. In addition, some machines use air laying technology and embossing to allow for a higher level of softness on the paper making it more pleasant while still maintaining some level of toughness for daily usage.

Efficiency in Production and Sustainability

Idealistically, every task does seek to have this singular quality distinguished from others, efficiency, when it comes to paper toilet tissue manufacturing on a large scale and growing demand for it – the focus becomes on the efficiency itself. In contemporary scenarios, the machinery is engineered in a manner that enhances production speed with ensuring the quality guarantees are still being met. Manufacturers are able to utilize automated systems to optimize operational levels, both minimising human interface as well as minimizing the production cost overall. Further, to cater the needs of the environmentally conscious, sustainable practices are also incorporated in the business model. For instance, a majority of paper toilet tissue paper machinery come equipped with energy-efficient motors that help in integrating used materials into the paper pulp and allowing for a bigger reduction on each roll created.

Market Preference and Demand Customization

Toilet tissue wenching transforms the toilet to paper machine to meet consumer preferences. Some buyers may want the product to be more strong, soft or even eco-friendly. The machinery is able to however customize by producing additional types of toilet paper such as single-ply, two-ply or even three-ply papers. In addition to this, the paper can provide distinct patterns and embossing designs to meet specific needs. Hence, the toilet tissue manufacturing machine becomes extremely useful for companies having diverse consumer needs due to its versatility.

Growing Consumer Needs of Softness Satisfaction

Softness is a good quality consumer seeks when on the toilet paper buying spree. High precision machinery, a trait of modern technology that such manufactures employ to ease their work assures clients of uniformity in large scale production to ensure comfort in all rolls that are available. Apart from the fact that the quality and end product is quite something on its own such machines go through thorough testing of the desired final product where they evaluate some of the necessary factors like texture, softness and ideal comfort. Employing such new technology enables manufacturers mitigate the steps involved in the process ensuring the delivery of toilet tissue paper that is desired by the end consumer in luxury and softness.

There have been significant improvements over the years with regard to toilet tissue paper machinery both technologically and from a sustainability standpoint. Given a forward-looking approach to production processes, the manufacturers have developed toilet paper which can provide softness over time while adhering to growing societal and ecological demands. With a high degree of efficiency, scope for further customization and a focus on sustainability, it is safe to say that Toilet Tissue Paper will rise to new heights, offering great comfort and luxury while also fostering a greener world. Due to progressive reforms in machinery, the market of toilet tissue paper seems promising with soft and robust as well as eco-friendly attributes in the future.

EN

EN

AR

AR BG

BG HR

HR DA

DA FR

FR DE

DE EL

EL PT

PT RU

RU ES

ES TL

TL ID

ID LV

LV LT

LT SR

SR SK

SK UK

UK VI

VI SQ

SQ GL

GL HU

HU TH

TH FA

FA AF

AF GA

GA HY

HY AZ

AZ KA

KA UR

UR BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KU

KU KY

KY