Exploring the Roles of Fluting, Testliner, Duplex Board, and Kraft Paper Machines

The Essential Roles of Fluting, Testliner, Duplex Board, and Kraft Paper Machines

Paper manufacturing depends on specialized machinery to meet different requirements across the industry. Take fluting paper for example it's really important in making those corrugated boxes we see everywhere. When sandwiched between the outer layers of cardboard, this material gives boxes their strength and helps protect whatever's inside. The way it's made allows it to soak up impacts and keep products safe while they travel from warehouse to customer. Because of how it's constructed, fluting offers better protection than old fashioned plastic padding options, which makes it not just practical but also greener. Plus, since most fluting paper can go right back into the recycling stream, manufacturers are finding it fits nicely with today's push toward environmentally responsible packaging solutions.

Testliner paper plays a key role too, thanks to how strong and resistant to tearing it actually is. Most testliner comes from recycled stuff these days, making it popular among packagers who need good quality box liners. What makes this material stand out is that it can handle quite a bit of weight without breaking down, something really important when keeping products safe during transport. Plus, companies find testliner affordable because manufacturers make it sustainably. They use fewer new materials overall, so there's less waste going into landfills. And despite being made from recycled content, testliner still performs just as well as traditional options on the market today.

Duplex board stands out thanks to its smooth finish and impressive rigidity, which makes it great for printing high quality images and all sorts of packaging needs. Made up of two distinct layers, one side gets special treatment to work well with printers and other imaging equipment. We see this material everywhere in industries where looks matter a lot, especially when packaging consumer products. From boxes holding frozen meals to containers for makeup items, duplex board handles detailed designs and brand logos without issues. Its properties allow manufacturers to create eye catching packages across multiple markets where visual appeal plays a big role in sales success.

Kraft paper machinery plays a really important role in how paper gets made because these machines can handle so many different tasks while working efficiently. They create this strong kraft paper that people love using for all sorts of things like grocery bags, shipping sacks, and even some construction materials. What makes kraft special is that it comes from chemical pulp which gives it much better resistance when torn than regular paper types. This means packages stay intact during transport even when carrying heavy stuff or awkward shaped objects. Because of this combination of toughness and flexibility, businesses across various industries rely heavily on kraft paper for their packaging needs whether they're small shops or big manufacturers.

Key Features of Modern Paper Making Machines

Advanced Technology in Paper Machines

Today's paper making equipment comes packed with tech upgrades that completely change how things get made. Most modern installations now have automated control systems built right in. These systems cut down on errors during production runs while also slashing waste materials. The whole operation flows much better when everything works together properly, so we end up with consistently good quality products at the end of the line. Speaking of tech advancements, many facilities have started integrating IoT solutions lately. With real time monitoring capabilities through these connected devices, plant managers can spot problems long before they actually stop the machines. Predictive maintenance alerts help keep downtime to a minimum too, which means longer lasting equipment and better overall performance across the board.

Sustainability in Paper Production

The paper production business has really made sustainability a top priority lately because companies want to cut down on their environmental harm. New equipment being used in factories now helps with green practices through things like incorporating post-consumer waste into the process while cutting back on both water usage and electricity needs. Such changes help shrink carbon emissions and fit right into worldwide campaigns for protecting nature. A lot of modern machinery actually meets strict regulations set by environmental agencies, which pushes forward better recycling habits and ensures wood pulp comes from properly managed forests. For manufacturers looking to switch to greener ways of making products, this kind of investment makes sense both ethically and economically as it reduces long term costs associated with resource depletion.

Efficiency and Speed in Modern Machinery

Modern paper making machines work incredibly fast and efficiently, letting paper mills churn out massive amounts of product day after day. The speed translates into real money savings for businesses while keeping them ahead of competitors in the marketplace. What makes these machines so valuable? They come equipped with cutting edge drying systems and quick changeover mechanisms that give producers tremendous flexibility on the factory floor. Manufacturers can easily shift from producing newsprint to packaging materials or specialty papers without wasting hours on setup time. This kind of adaptability means companies stay responsive to whatever customers throw at them next. No wonder these high tech machines have become standard equipment across the industry.

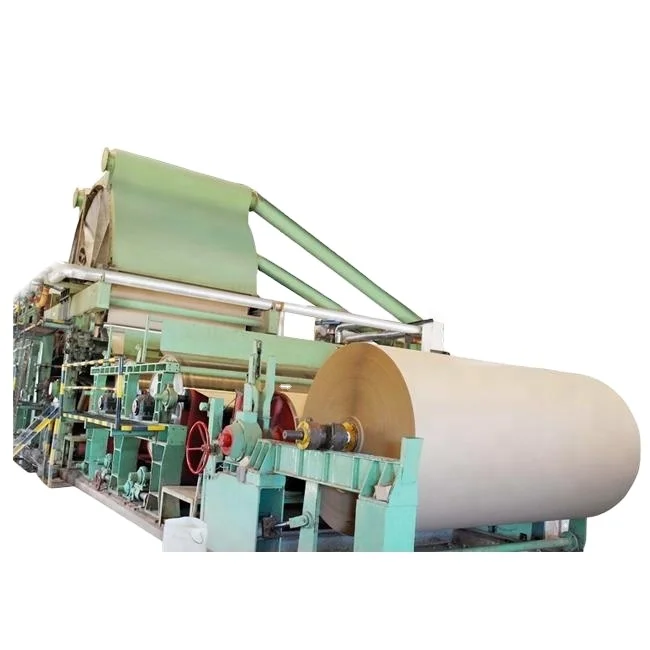

Wood Pulp Recycling Carton Box Kraft Paper Making Machine 2100mm

Overview of the Wood Pulp Recycling Machine

The Wood Pulp Recycling Carton Box Kraft Paper Making Machine takes regular wood pulp mixed with recycled fibers and turns them into quality kraft paper that holds up well under pressure. By focusing on reused materials first, this system tackles environmental concerns head on while also catering to consumers who increasingly want greener alternatives in their everyday purchases. What really sets this machine apart is how flexible it actually works in practice. Operators can run everything from virgin pulp to old cardboard boxes through the same equipment without much adjustment needed. For small scale producers looking to cut costs but still maintain standards, or larger facilities wanting to diversify their output, this kind of adaptability means significant savings over time when compared to traditional manufacturing setups.

Technical Specifications and Capabilities

The 2100mm wide wood pulp recycling machine was built specifically for medium to large scale operations that need reliable performance day after day. With cutting edge pulping tech and drying systems that run themselves most of the time, this equipment maintains consistent paper quality without needing constant operator attention. The automatic controls really cut down on manual labor, something plant managers appreciate during busy production periods. These specs translate into serious output numbers too, making it possible for facilities to handle big orders without breaking a sweat when demand spikes.

Applications in Kraft Paper Production

This machine plays a big role in manufacturing different types of kraft paper goods, which makes sense for packaging and shipping needs since the paper comes out pretty tough and long lasting. What's interesting too is how the equipment actually helps with recycling efforts across the sector. By working with materials that have already been used before, companies can cut down on waste while still getting quality product. Recycled content isn't just good for the planet these days either many businesses find their customers appreciate seeing eco friendly options on store shelves.

Henan Automatic Carton Board Paper Machine

Features of the Henan Automatic Machine

Henan's automatic machine comes loaded with cutting edge tech that cuts down on mistakes made by humans while keeping production consistent across batches. The tech gives operators pinpoint control during paper making, something that really matters when trying to maintain product quality standards. What sets this apart is its easy to navigate interface panel that slashes training time for new staff members. Operators can get up to speed much faster than with older models. Plus, the way it's designed lets companies switch between different paper types or ramp up production without major headaches. For paper manufacturers facing stiff competition, this kind of flexibility means they stay ahead of market changes rather than constantly playing catch up.

Production Capacity and Output

Henan Automatic Machine handles serious production workloads, which makes it perfect for companies needing lots of output without sacrificing quality standards. The machine has plenty of power to keep running smoothly even when factories are cranking out products at scale. What sets this equipment apart is its focus on getting things done quickly between production runs. Engineers built it with features that cut down on those annoying stoppages between batches. For manufacturers trying to squeeze every last minute out of their production schedule, this matters a lot. They can churn out more goods without letting quality slip, something critical when orders pile up fast. Companies using this machine report better delivery times across the board, which naturally keeps customers happy and coming back for more.

Applications in Carton Board Production

The machine does an outstanding job making top quality carton board needed for all sorts of things from eye-catching display boxes to food packaging and tough shipping containers that can handle rough handling during transport. What sets it apart is how adaptable it is when it comes to working with different board thicknesses and surface treatments, so manufacturers aren't limited in what they can produce for various sectors. The ability to switch between production specs gives companies room to develop tailored packaging options that stand out in crowded markets. From small retail packages to heavy duty industrial containers, the Henan Automatic Machine consistently churns out durable carton board products that hold up well under stress tests and satisfy strict industry specifications across multiple markets.

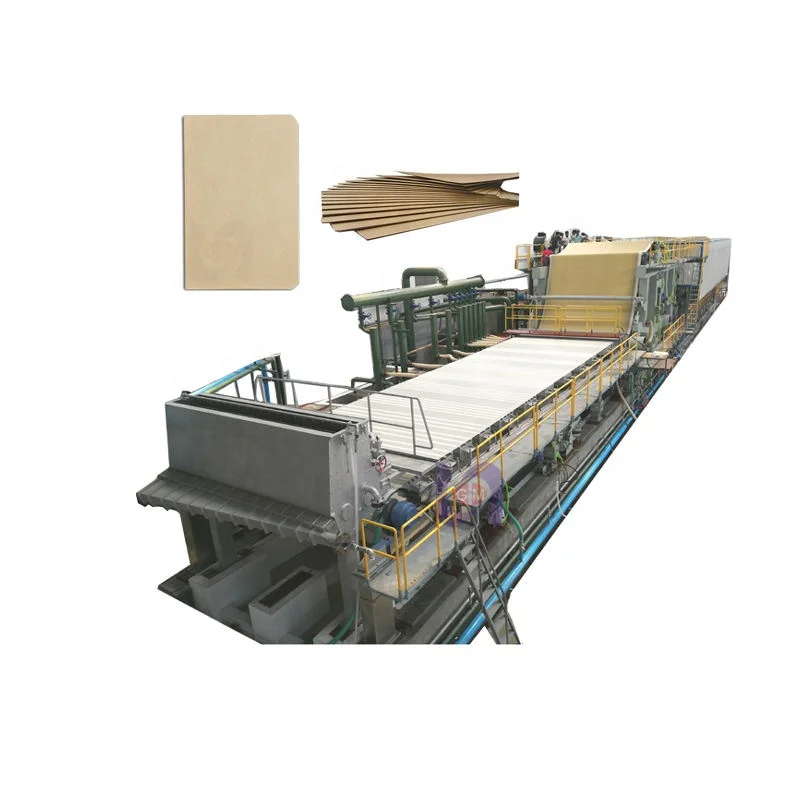

Guangmao High Quality Kraft Paper Making Machine

High-Quality Kraft Paper Production

The Guangmao kraft paper machine produces top quality paper that meets all the industry requirements, so it works great for pretty much any kind of packaging job out there. What makes this machine stand out is how strong and tough the resulting paper turns out to be something that matters a lot when companies need reliable materials for things like shipping boxes or product wrapping. The machine takes different inputs including old newspapers, fresh wood pulp, plus various other recycled stuff and actually manages to turn these raw ingredients into really durable kraft paper without much waste in the process.

Technical Details and Performance

The Guangmao Kraft Paper Making Machine comes packed with some seriously impressive tech that makes paper production run smoothly and efficiently. What really stands out are its automatic control systems paired with those super effective drying capabilities. These features cut down on production time while actually improving the final paper quality too. Built tough from the ground up, this machine can handle all sorts of demanding workloads without breaking a sweat. Manufacturers will appreciate how it keeps performing reliably day after day, week after week, delivering consistent results even when pushed hard during busy production periods.

Applications in Various Industries

The Guangmao Kraft Paper Making Machine handles a wide range of industrial requirements by manufacturing kraft paper that finds its way into everything from everyday packaging to specialized protective materials. For companies looking to go green, this machine becomes essential since it makes possible the creation of truly sustainable products that replace plastic alternatives. What sets this equipment apart is how flexible it really is. Businesses can crank out different types of paper suited for all sorts of purposes, from food grade packaging to heavy duty shipping materials. This adaptability means manufacturers can meet specific industry demands while still hitting those important sustainability targets that are becoming so crucial in today's competitive paper market.

Support 5 Tons/Day 2100mm Recycled Paper Pulper Kraft Paper Making Machine

Efficiency in Recycled Paper Processing

The Support 5 Tons per Day 2100mm Recycled Paper Pulper for Kraft Paper Production stands out when it comes to getting things done efficiently without burning through power. What makes this machine special? Well, it handles large volumes quickly while keeping energy usage down compared to traditional methods. The way it's built actually streamlines the whole recycling process from start to finish something manufacturers really need these days as sustainability becomes standard practice across industries. When companies want to cut down on material waste and run operations using greener techniques, machines like this become indispensable tools in their arsenal against rising disposal costs and customer demands for environmentally responsible products.

Technical Specifications and Features

With its solid build measuring 2100mm wide, this machine stands up to years of tough operation thanks to some pretty smart tech inside. What makes it special? Well, it can tackle all sorts of recycled stuff from plastic bottles to old metal parts, which helps cut down waste throughout different sectors. Built to last through heavy duty cycles, the machine handles everything from lightweight scraps to denser materials without breaking a sweat. For businesses serious about their green initiatives, this equipment isn't just useful it's practically essential when trying to maintain consistent recycling operations while keeping costs under control.

Applications in Sustainable Paper Production

The machine is really important for making kraft paper completely out of recycled stuff, which fits right into what many industries want these days when it comes to green products. What makes this setup stand out is how it creates quality paper products even though everything comes from recycled material. Businesses can keep their standards high but still meet those environmental goals they need to hit. For manufacturers trying to go green, this equipment offers something practical. Companies looking to reduce waste and cut down on virgin material costs find themselves relying on machines like this one because they actually work well in real world conditions.

2400Mm 25Tons Kraft Paper Machine Line

High-Capacity Kraft Paper Production

The 2400mm 25 Ton Kraft Paper Machine Line was built to handle big volume production needs right from the factory floor up. Industrial plants love this setup because it keeps everything moving smoothly while cranking out tons of product daily. What really matters to plant managers is how this equipment makes better use of pulp resources and cuts down on material waste during operation. For companies running tight budgets, these efficiencies translate directly to real money saved month after month. Many paper mills report seeing significant reductions in their operational costs within just a few months of installation, all while maintaining consistent quality standards across their entire production run.

Technical Specifications and Capabilities

The 2400mm 25 Ton Kraft Paper Machine Line comes packed with advanced control systems and runs at impressive speeds, which makes it well suited for today's industrial production requirements. The machine can handle paper widths up to 2400mm, giving manufacturers the flexibility they need to produce different types of paper products according to customer specifications. This kind of versatility really matters when trying to keep up with changing market demands. For paper producers looking to stay ahead of competition, having such a machine on site provides significant advantages. It helps maintain consistent product quality while also boosting overall production efficiency across various paper manufacturing operations.

Applications in Large-Scale Paper Manufacturing

The kraft paper machine line works really well for big manufacturing operations, especially those in packaging or making construction materials. When companies need to process huge order volumes, this equipment keeps up without sacrificing quality standards, which means customers generally come back happy. What sets it apart is its consistent output of good quality kraft paper. For businesses where reliability matters most and strict quality checks are part of daily operations, this kind of performance makes all the difference. Companies can meet their operational goals while staying competitive in markets where environmental factors play a growing role in purchasing decisions.

EN

EN

AR

AR BG

BG HR

HR DA

DA FR

FR DE

DE EL

EL PT

PT RU

RU ES

ES TL

TL ID

ID LV

LV LT

LT SR

SR SK

SK UK

UK VI

VI SQ

SQ GL

GL HU

HU TH

TH FA

FA AF

AF GA

GA HY

HY AZ

AZ KA

KA UR

UR BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KU

KU KY

KY