Technical Insights into Toilet Tissue Paper Processing Machinery

Understanding Toilet Tissue Paper Processing Machinery

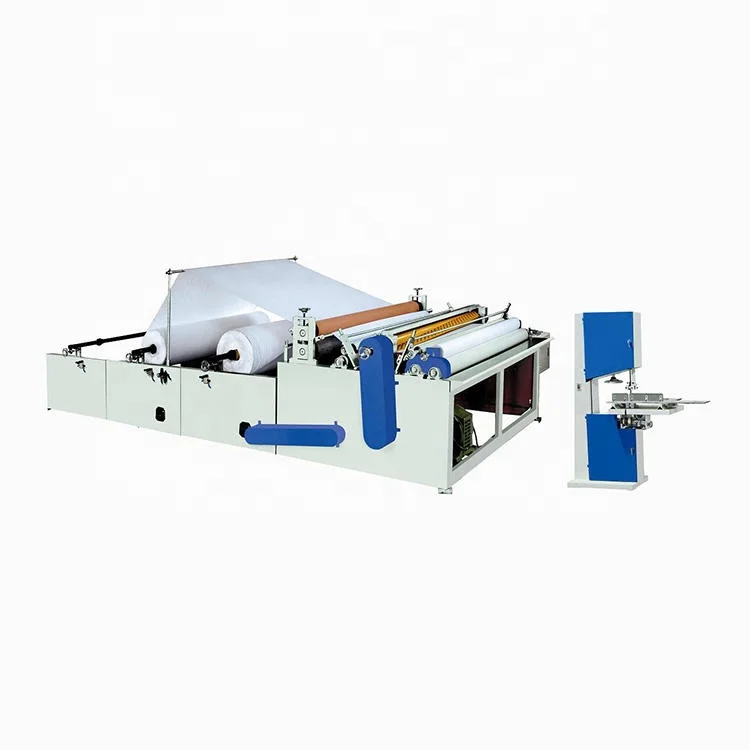

Tissue paper machines used for toilet paper production go by many names, but they're basically what keeps the whole industry running smoothly. These industrial beasts make things much faster on factory floors, cut down wasted time between batches, and keep each roll looking pretty much the same from one box to another. What really matters about them though is how they crank out tons of tissue products day after day without missing a beat. Manufacturers need this kind of output to satisfy customers who want their bathroom essentials both gentle on skin and tough enough to last through multiple uses. Plus, getting that exact same feel and thickness across every single sheet remains crucial for brand reputation in a market where quality differences can make or break sales.

To really understand how toilet tissue paper gets made, we need to look at the machinery design and how automated these systems actually are since this affects both how much gets produced and what ends up as waste. These days most paper machines come loaded with smart automation tech that boosts production rates while cutting down on mistakes, which obviously means less wasted material. When manufacturers install cutting edge control systems, they gain much better grip on the entire manufacturing process so each roll meets quality standards consistently. All this fancy equipment isn't just about making money either it helps companies hit their green targets too because when there's less waste going into landfills, everyone wins environmentally speaking.

Types of Toilet Tissue Paper Processing Machinery

Toilet tissue paper processing machinery comes in several forms, each suited to specific production needs ranging from small-scale operations to large industrial facilities. Understanding the different types of machinery available is crucial for businesses aiming to optimize their production efficiency and meet market demands.

Manual vs. Semi-Automatic vs. Fully Automatic Machines

Different types of machines manual, semi-auto, and fully automatic ones cater to various business sizes and requirements. Small shops often go for manual equipment since they don't cost as much upfront, though operators have to put in a lot of work. Makes sense when money is tight, right? Semi automatic models sit somewhere between the extremes. These bad boys boost productivity compared to purely manual systems but still need someone watching over things occasionally. The balance tends to work out pretty well for mid sized operations. Then there's the big leagues with fully automatic machinery. These beasts lead the pack when it comes to getting stuff done fast and accurately. Less chance of mistakes happening because humans aren't involved in every step anymore. Perfect fit for factories cranking out thousands of units daily. Once set up properly, automated systems keep churning out consistent products without breaking a sweat.

Specialized Machinery for Different Production Scales

Production facilities come in all sizes, and each needs its own type of equipment to manage output effectively. Small workshop owners often find value in space-saving machines that make the most of what little room they have available. Big manufacturing plants meanwhile rely on heavy duty equipment built for speed and versatility across different types of toilet paper products. Getting the right kind of machinery for your operation size really matters for keeping things running smoothly without breaking the bank or falling behind competitors. Machines with variable speed controls and the ability to switch between paper grades become essential when trying to meet varied customer demands. The whole point is matching machine specs to actual production needs, which ultimately boosts productivity and helps businesses stand out in crowded markets.

Key Features of Modern Toilet Tissue Paper Machines

Automation and Efficiency in Toilet Tissue Paper Production

Toilet paper manufacturing has changed quite a bit lately thanks to all sorts of new automation tech and efficiency upgrades in the machines themselves. The latest models come equipped with fancy sensors and computer controlled systems that keep tabs on everything happening during production right as it happens. This real time monitoring helps catch problems before they become big issues. When companies cut down on wasted materials and get better at using their resources, the whole operation tends to run smoother day after day without needing someone constantly watching over every step. What this means practically is faster turnaround times for batches of toilet paper, which translates into real money savings when markets shift around unpredictably from month to month.

Sustainability and Eco-Friendly Features

Manufacturers making modern toilet tissue paper machines have started putting sustainability front and center in their operations. Many companies now incorporate recycled fibers into their products while switching to greener manufacturing methods across the board. The latest models come equipped with energy saving technologies and consume far less water than older versions, which helps them comply with international green regulations and appeals to customers who care about environmental impact. With growing interest in sustainable living, these improvements cut down on running expenses for businesses too. Plus they give manufacturers an edge in today's crowded marketplace where shoppers actively seek out brands committed to real environmental progress rather than just marketing buzzwords.

Applications of Toilet Tissue Paper Processing Machinery

Industrial Applications of Toilet Tissue Paper Machines

In industrial environments, toilet tissue paper machines are absolutely critical for churning out massive amounts of toilet paper that businesses need every day. Places like hotels, restaurants, and shopping malls depend heavily on these machines to keep their bathrooms stocked with necessary hygiene supplies. What makes these paper production systems so efficient? They can run nonstop throughout the day and night, cutting down on expensive downtime and keeping operational expenses low. Plus, many facilities now have automated packaging lines that speed up the whole process, making it easier to get product out to stores and other commercial locations quickly. The sheer volume of toilet tissue being produced industrially today matches up nicely with the skyrocketing demand we've seen lately, especially after events like the global health crisis really put hygiene products front and center for everyone.

Small-Scale Production and Custom Solutions

For smaller operations, investing in toilet paper machines built for modest production volumes opens doors to niche markets looking for something different than mass-produced options. These compact systems still hit all the quality checkpoints so local makers can put out great stuff without cutting corners. What really sets them apart though is their versatility. Manufacturers can tweak things like thickness, softness levels, even add scents or colors based on what customers want right now. Take eco-conscious buyers for instance who prefer recycled content or biodegradable options. Or maybe there's a demand for thicker bathroom tissue in certain regions. Being able to adjust quickly means these businesses stay competitive while keeping costs manageable in specialized segments where big brands aren't always present.

Top Products in Toilet Tissue Paper Processing Machinery

2024 New 2200mm Kraft Paper Machine

The new 2200mm Kraft Paper Machine from 2024 really pushes the boundaries of what's possible in paper manufacturing these days. Built with efficiency at its core, this machine cuts down on waste while speeding up production times significantly compared to older models. What makes it particularly valuable is its ability to switch between different paper types seamlessly. Manufacturers can run everything from standard kraft paper to specialized corrugated fluting paper without needing separate equipment. This flexibility means companies don't have to invest in multiple machines just to handle their varied order requirements, which saves both space and money in the long run.

Best Price Jumbo Roll Toilet Tissue Paper Making Machine

For companies looking to boost their production without breaking the bank, the Best Price Jumbo Roll Toilet Tissue Paper Making Machine offers an affordable way to get things done. Built with practicality in mind, this machine comes packed with reliable components that are easy to maintain, which means manufacturers can keep producing those big rolls without spending a fortune on repairs or downtime. What really stands out is how versatile it actually is. The machine works well with different kinds of paper materials, making it especially attractive for folks running tight budgets but still needing quality output. Many small to medium sized operations have found success using this equipment because it delivers solid performance at prices that make sense for most business owners.

Automatic Toilet Paper Rewinder Tissue Paper Manufacturing Machine

For manufacturers looking to cut down on manual work and boost productivity, the automatic toilet paper rewinder tissue paper manufacturing machine has become something of a game changer. What this equipment does basically is take all that raw material and turn it into those neat little rolls we see on store shelves. Pretty smart stuff too since it comes equipped with tension controls that help keep quality consistent throughout the whole batch. And let's not forget about those adjustable speed settings which make it possible to handle different production demands without missing a beat. The result? Rolls that hold together well and last longer than what many competitors can offer these days.

High Efficiency Waste Paper Recycling Egg Tray Molding Machine

The High Efficiency Waste Paper Recycling Egg Tray Molding Machine turns discarded paper into useful egg trays while helping companies go green. What sets this equipment apart is how it expands what manufacturers can produce from recycled materials, all while cutting down on factory waste. Running this machine actually saves money on raw materials too, which explains why so many producers are switching to it these days. For businesses trying to meet their environmental targets, investing in such technology makes both ecological and economic sense without compromising quality standards.

Future Trends in Toilet Tissue Paper Machinery

Technological Advancements in Toilet Tissue Paper Processing

The latest tech improvements in toilet tissue paper production equipment are set to shake things up across the industry. Looking ahead, we can expect to see better automated systems that require less manual intervention, along with IoT technology being built into machines so operators get instant feedback on how everything is running. Energy savings will also become a bigger focus with newer models consuming less power during operation. For manufacturers wanting to stay competitive, these upgrades mean they can run their facilities smoother with fewer breakdowns and higher output rates. As consumer preferences shift toward different paper qualities and specialty products, companies are pouring money into R&D departments to create machines that handle multiple paper grades without needing extensive reconfiguration. What's really interesting is that many of these technological advances actually help cut down on energy waste while still maintaining high production standards, which makes good business sense in today's environmentally conscious market.

Market Growth and Emerging Opportunities

Toilet tissue paper machinery markets are looking at serious growth thanks to people wanting better quality tissue products than ever before. Manufacturers have plenty of room to grow their businesses and grab bigger slices of the pie. With living standards going up across many developing countries, entirely new markets are popping up where there was nothing before. Take a look at places like the Middle East where folks are earning more money now and starting to care more about staying clean. The World Factbook shows interesting numbers from countries such as Saudi Arabia, United Arab Emirates, and Egypt. These nations aren't just buying more tissue products but actually investing in brand new machinery installations planned for the next couple years. What we're seeing here isn't just another passing trend but real opportunity for companies willing to innovate within the tissue paper sector.

EN

EN

AR

AR BG

BG HR

HR DA

DA FR

FR DE

DE EL

EL PT

PT RU

RU ES

ES TL

TL ID

ID LV

LV LT

LT SR

SR SK

SK UK

UK VI

VI SQ

SQ GL

GL HU

HU TH

TH FA

FA AF

AF GA

GA HY

HY AZ

AZ KA

KA UR

UR BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KU

KU KY

KY