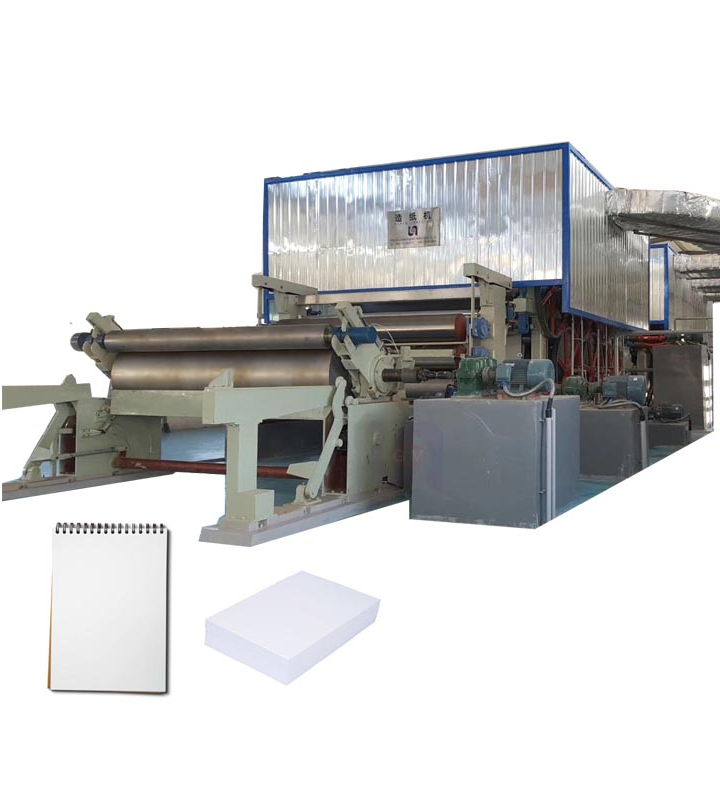

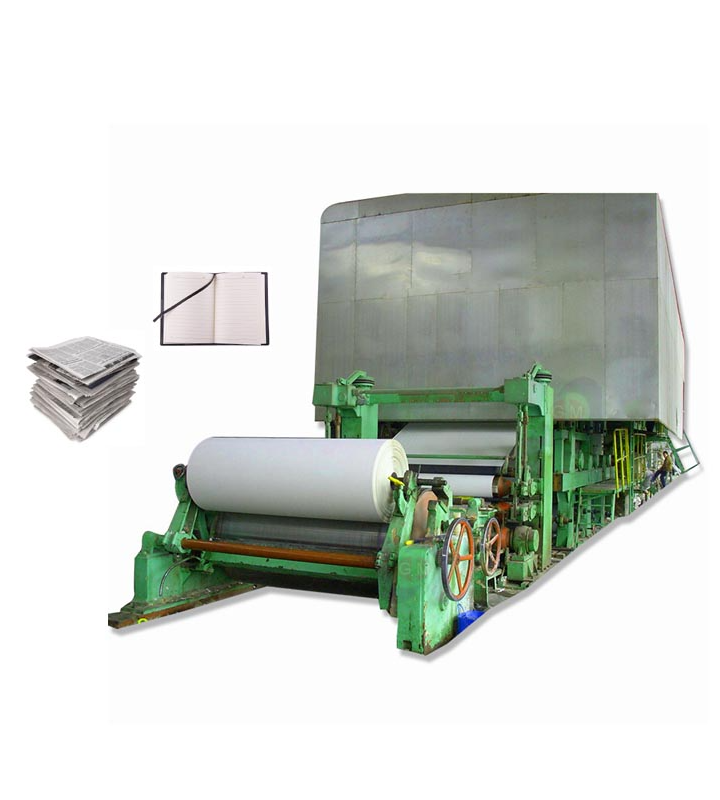

For big production, GM Machinery printing paper machine is designed to produce high-quality printing papers. Our machines are integrated with modern technology which improves efficiency in production while maintaining the standard and uniformity of the product. These printers can be used in making books, newspapers among other reading materials. With trustworthy controlling systems and strong buildings, this printer will offer your plant a sustainable answer hence reducing costs incurred during manufacturing thus increasing competitiveness within the market.

GM Machinery endeavors to offer worldwide support for paper recycling machines. This is made possible by our team of highly skilled experts located in various parts of the globe. They assist from installation through continuous maintenance and upgrading of the machine. We have a dedicated group that works with clients in order to improve on efficiency as well as troubleshooting problems thereby optimizing performance Meanwhile, we also prioritize customer satisfaction and operational reliability into account so much such that they are necessary requirements for any successful business venture at GM machinery; thus ensuring value addition through innovation still takes place even after many years since they were first introduced thereby making them useful forevermore while enabling paper manufacturers thrive more sustainably within competitive markets.

GM Machinery knows that all paper recycling plants have different needs. This is the reason why we present personalized answers designed for specific recycling problems. Our equipment can optimize sorting methods, improve pulping productivity or enhance deinking potentiality among other things. In addition to this, such machines are created with an aim of providing uniform quality and performance throughout. Process engineering and material handling are areas where GM machinery boasts its proficiency so as to ensure fiber recovery efficiency and product excellence for our clients. Our main concern being reliability coupled with operational efficiency; it follows then that these recycling systems enable manufacturers save on money while doing less harm to the environment.

GM Machinery is known for establishing benchmarks in the area of efficiency and dependability as far as paper recycling machines are concerned. We manufacture our systems using strong parts and sophisticated automation technology which guarantees less breakdowns caused by maintenance requirements. Controls that keep track of everything at all times allow us to use the best settings possible thus ensuring constant quality during production runs. Performance is always the priority with our equipment; be it adjusting screeners or fine tuning pulpers — we designed them for peak performance every time! What this means is simple – through operational streamlining coupled with efficient resource application throughout various stages within their life cycle, these devices promote sustainable development among clients while spurring competitiveness within paper recycling industry itself.

GM Machinery is the most advanced company in the sector because it has created modern paper recycling machines that changes waste paper into valuable recycled items like no other. Any kind of paper can be used in our machines; we have designed them so that they can work with newspapers or packaging materials among others, and this is done with high levels of efficiency and low environmental impact. GM Machinery adopts the latest pulping technology which involves using screens and deinking agents during separation processes thus ensuring that more fibers are recovered while less energy is consumed together with water. It should be noted also that what drives us towards innovating new equipment for recycling papers is our desire to practice sustainable manufacturing methods as well as taking care of the environment.

Zhengzhou Guangmao Machinery Manufacture Co. LTD, based in Zhongyuan District, Zhengzhou, specializes in manufacturing paper making and processing machines. With over 30 years of experience and technology imported from Germany and Italy, they offer a range of advanced products. They provide OEM and design services, boasting CE and ISO certifications. Their commitment to quality and customer satisfaction is evident through partnerships with over 25 countries, ensuring a strong global reputation for excellent products and service.

Efficient molding process for eco-friendly packaging.

High-speed production with excellent strength-to-weight ratio.

Produces strong, recyclable paper for versatile packaging solutions.

Delivers soft, absorbent tissue rolls for premium hygiene.

Our company manufactures a variety of printing paper machines tailored for different production needs, including offset printing, digital printing, and specialty paper machines for high-quality prints.

Our machines are equipped with advanced features such as precise coating application, uniform drying systems, and automated quality control. These technologies ensure that the paper maintains smoothness, brightness, and dimensional stability crucial for superior printing results.

When selecting a printing paper machine, it's essential to consider factors such as paper width and weight capacity, printing speed, drying capabilities, customization options for different paper grades, and integration with existing printing processes.

Yes, our machines are designed to handle various types of printing inks including offset, flexographic, and digital inks. They also support different finishes such as matte, gloss, and satin coatings, ensuring versatility for diverse printing applications.

We provide comprehensive support services including installation, commissioning, operator training, preventive maintenance programs, spare parts availability, and technical support. Our goal is to ensure optimal performance and maximum uptime of your printing paper machine.