Anti-Scaling Solutions for Printing Paper Coating Rollers

Understanding Anti-Scaling Challenges in Paper Coating Rollers

Common Causes of Scaling in Printing Paper Machinery

Paper machinery tends to develop scaling problems mainly because minerals build up from the water used during coating operations. When these mineral deposits accumulate inside the equipment, they start causing all sorts of operational headaches down the line. What makes matters worse are the chemical reactions that happen when certain additives get mixed into paper coatings, which leads to scale formation that really messes with how machines run smoothly. Things get even trickier when pH levels go off track or temperatures fluctuate during production runs, both of which tend to make scaling issues much worse. Using recycled water regularly brings along various impurities that just compound the existing problems. For anyone running a paper mill, understanding where these scaling problems come from isn't just helpful it's absolutely necessary for putting together proper prevention strategies so that production stays on schedule without constant machine breakdowns.

Impact of Scaling on Production Efficiency

When scaling builds up in paper machinery, it really messes with how efficiently things run because there's so much downtime needed for regular maintenance and cleaning tasks. All this stopped time means operations get delayed, and companies lose money as a result. What's worse, scaling affects the quality of the final product too. We end up with more waste and extra costs from rejected batches that don't meet standards. Another problem comes from all that buildup reducing how well the machines transfer heat. This makes them consume more energy overall, driving up operating expenses month after month. For toilet paper manufacturers specifically, ongoing scaling problems create uneven print quality across rolls, something customers definitely notice and complain about. To convince management to spend on anti-scaling treatments, plant managers need solid numbers showing exactly how much money gets lost when scaling isn't controlled properly.

Advanced Anti-Scaling Coating Technologies

PTFE and Fluoropolymer Coatings for Heat Resistance

PTFE, or Polytetrafluoroethylene, stands out because it handles heat really well, something that makes all the difference when trying to stop scaling problems in paper machines. When applied as a fluoropolymer coating, PTFE forms surfaces where materials just don't stick, so there's much less buildup over time. The real benefit comes from how these coatings hold up under the intense heat conditions found during paper coating operations, often reaching temperatures around 300°C without breaking down. Industry data suggests equipment with such coatings experiences scaling issues maybe 40% less frequently compared to traditional setups. For manufacturers dealing with constant maintenance headaches from scale accumulation, this represents not just a technical improvement but also substantial cost savings in downtime and cleaning requirements across their production lines.

Ceramic and Electroless Nickel Coatings for Durability

Ceramic coatings stand out because they're really hard and resist corrosion pretty well, which makes them great for parts that get worn down fast in paper machines. Electroless nickel coatings work differently but also have their advantages. They create even layers across different materials and stick to surfaces better than many alternatives, so components last longer overall. For companies running paper mills and tissue production lines, both options help extend machine life spans without needing constant part swaps. The bottom line is simple math for plant managers looking at budgets: spending money upfront on quality coatings pays off big time later when repair bills shrink and downtime drops significantly.

Benefits of Non-Stick Surface Treatments

Non stick coatings on surfaces play a big role in cutting down friction between rollers and various coating materials, which leads to much smoother operation inside the machinery itself. These special treatments help prevent scale from building up over time while also making regular cleaning jobs easier and actually getting results faster. When manufacturers apply these non stick coatings across their equipment, they tend to see fewer interruptions during production runs, so everything runs better day after day. Industry reports show actual improvements in final product quality too, especially when looking at reduced defects caused by scaling issues. For paper mills specifically, this means higher throughput rates and less downtime spent fixing problems that could have been avoided with proper surface treatment strategies in place.

Featured Anti-Scaling Solutions for Paper Production

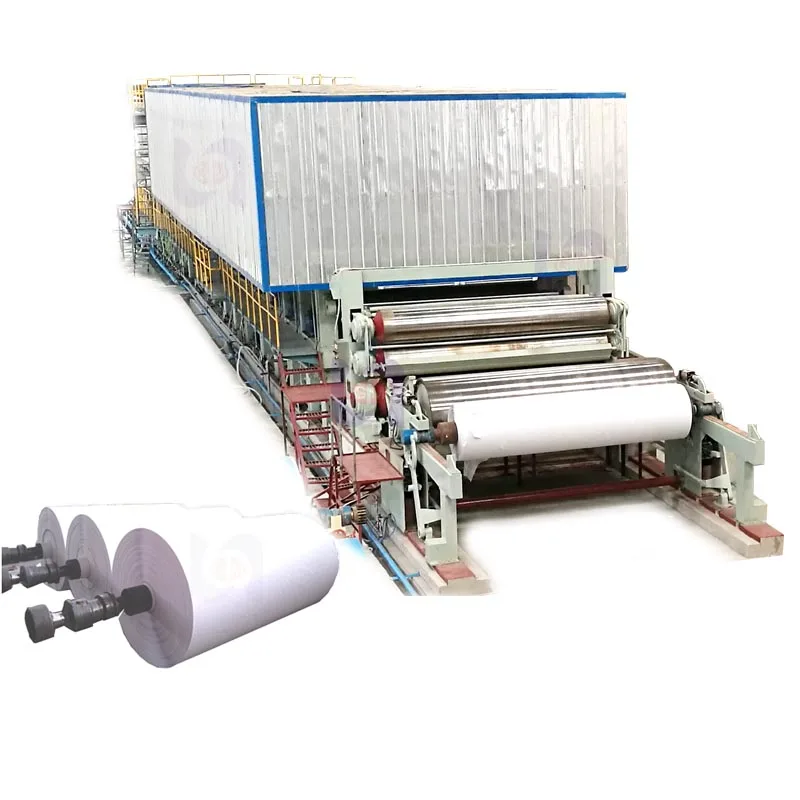

Guangmao Culture Paper Manufacturing Machine

The Guangmao Culture Paper Manufacturing Machine brings real innovation to the table with its cutting edge anti-scaling tech that makes paper production run smoother than traditional methods. Industry folks who actually work with these machines day in and day out report that maintenance costs drop dramatically when scaling becomes less of an issue. What sets this machine apart are the smart systems it comes equipped with for managing water and chemicals throughout the process. These systems help keep scaling at bay most of the time, so factories can maintain their output without constant interruptions. For paper mills looking to cut expenses while keeping production levels steady, this machine offers some serious advantages over older equipment.

Fourdrinier-Type Waste Paper Recycling Machine

The Fourdrinier type waste paper recycling machine handles recycled materials pretty well while keeping scaling issues at bay. Special coatings on various parts stop those pesky scale deposits from forming, which means the machine lasts longer and keeps running smoothly even after years of operation. What really sets this equipment apart though is its incorporation of cutting edge recycling tech that actually supports green manufacturing goals. For companies serious about reducing their environmental footprint, these machines offer real value since they help cut down on resource consumption during the papermaking process without sacrificing output quality.

Maintenance Strategies to Prevent Roller Scaling

Routine Cleaning Protocols for Coating Rollers

Creating a cleaning routine tied to how often machines run really helps cut down on scale buildup before it becomes a problem. When we keep up with regular maintenance, those pesky mineral deposits don't get a chance to stick to the rollers, something that keeps our equipment running smoothly. Special cleaners work wonders too - they eat away at those stubborn deposits without harming the machinery itself. And let's not forget training the team properly either. Workers who know exactly how to clean things right make all the difference in extending roller life and keeping operations efficient. Less downtime means fewer repair bills down the road. Most shops find this kind of detailed attention fits right into standard cleaning practices while doing a great job at stopping scale issues before they start causing headaches.

Optimizing Machine Settings for Scale Prevention

When papermakers tweak the temperature and pressure settings on their machines, they actually have a big impact on how much scaling occurs during production. Getting those settings right stops scaling problems while making sure the final product meets quality standards. Keeping an eye on pH levels in coating fluids matters too because this directly affects whether scale builds up over time. Manufacturers who spend time adjusting these factors see less waste material going into landfills, which saves money and keeps equipment running smoother longer. Proper machine calibration remains one of the most effective ways paper companies fight against scale buildup that plagues many manufacturing operations.

Collaborating with Papermaking Machine Manufacturers

When paper mills work hand in hand with their machine suppliers, they get first dibs on new anti-scaling tech that hits the market. These manufacturers know their stuff inside out and can give real world guidance about adjusting machine parameters and keeping equipment running smoothly for different types of production runs. The partnership matters because it actually results in better scaling prevention methods designed specifically for what papermakers deal with day to day. Paper companies that tap into manufacturer knowledge see real improvements in how well their machines perform over time while also cutting down on maintenance headaches. This kind of collaboration isn't just good for today's operations but helps build sustainable practices that stand the test of time.

EN

EN

AR

AR BG

BG HR

HR DA

DA FR

FR DE

DE EL

EL PT

PT RU

RU ES

ES TL

TL ID

ID LV

LV LT

LT SR

SR SK

SK UK

UK VI

VI SQ

SQ GL

GL HU

HU TH

TH FA

FA AF

AF GA

GA HY

HY AZ

AZ KA

KA UR

UR BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KU

KU KY

KY