Faster Setup Tactics in Small-Batch Toilet Paper Machine Runs

Essential Pre-Run Checks for Efficient Small-Batch Operations

Machine Calibration Best Practices

Getting machines properly calibrated makes all the difference when it comes to precision work in small batch manufacturing. Most shops find that scheduling regular checks about every 500 hours of operation keeps their equipment running accurately. Taking this kind of preventive maintenance actually cuts down on mistakes and boosts how well production runs go overall. When doing calibrations, always reach for those official certification tools they sell specifically for this purpose. They really do make a noticeable improvement in accuracy, cut back on material waste, and save money long term. Don't forget to check key numbers like pressure settings and feed rates before kicking off any new production run either. Catching problems at the start instead of halfway through saves everyone headaches later. Good calibration habits not only keep product quality consistent but also means fewer unexpected stoppages that eat into productivity.

Material Readiness Verification

Getting materials ready before production starts helps avoid those annoying operation problems everyone hates. First things first, make sure the raw stuff coming in is actually good quality and the right kind for what needs to be made. Working with suppliers who have proper certifications cuts down on contamination issues and defective batches quite a bit. The end result? Products that actually match up to what customers expect. Inventory counts matter too. Nobody wants to hit a wall halfway through because there's nothing left in stock. That kind of stoppage costs money fast. Don't forget about checking moisture levels either. Too much water content in raw materials messes with how everything turns out later. Some companies skip this step and wonder why their batch looks different than usual. Taking time to do all these checks upfront means fewer headaches down the line and better quality stuff rolling off the line week after week.

Streamlining Changeover Processes in Toilet Paper Production

Quick-Release Mechanism Utilization

Quick release mechanisms really cut down on downtime when switching products in toilet paper manufacturing. When machines have parts that snap right out and in, production lines move much smoother between different runs without those annoying stoppages. Getting staff properly trained on how these quick release systems work isn't just nice to have either. Workers need to know exactly where everything goes and how fast they can swap things over. Once everyone's comfortable with the system, changeovers happen faster and mistakes drop off dramatically. Keeping track of actual changeover times helps managers see what's working and what needs fixing. Looking at these numbers regularly shows where improvements can be made, which means the whole process keeps getting better over time as teams learn what works best for their particular setup.

Parallel Task Execution Strategies

When teams create workflows that let them run several tasks at once during equipment changeovers, it really boosts how efficiently toilet paper plants operate. Plants that implement this strategy often see fewer holdups and faster switch times between different paper grades. Most manufacturers swear by good old fashioned checklists to make sure nothing gets missed when switching production lines. A simple piece of paper with boxes to tick off keeps everyone on the same page and prevents those frustrating moments where someone forgets to adjust a critical setting. Some companies have started using digital timers and stopwatches to track exactly how long each parallel task takes. Looking at this data helps spot where things tend to slow down, which makes sense because nobody wants their plant grinding to a halt just before meeting daily quotas. The best part? These small adjustments compound over time, leading to smoother operations without requiring massive capital investments.

Top 5 Machines for Small-Batch Toilet Paper Manufacturing

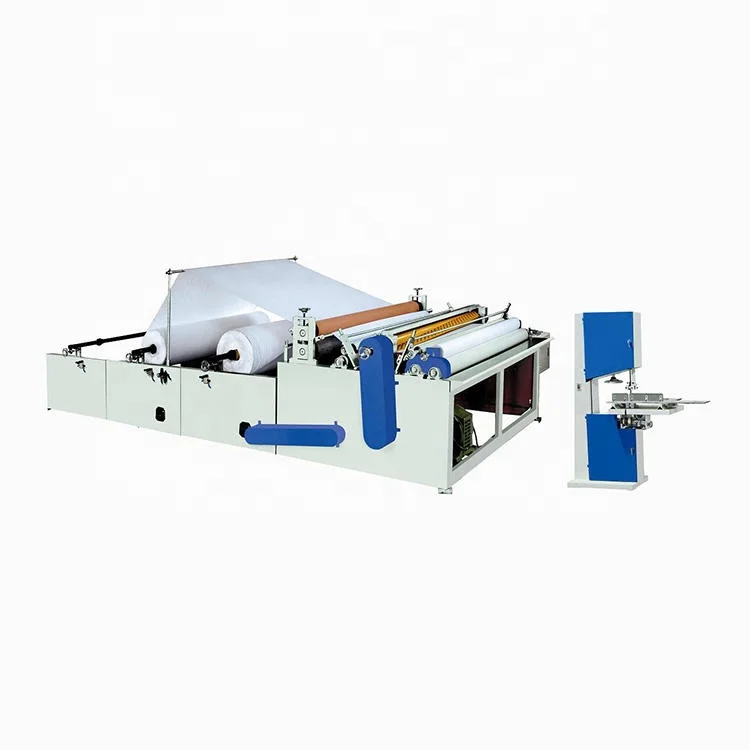

Professionally Designed Automatic Toilet Paper Rewinder Reliable Quality Assurance

Automatic toilet paper rewinders designed with professional engineering really boost how efficiently operations run while keeping products consistent from batch to batch. These machines work with precise automation that creates uniform results every time, something manufacturers need when they want to keep up quality standards. Research from manufacturing sectors indicates that facilities using such automated equipment see better production results because there's less chance of mistakes happening during manual processes plus workflows move faster overall. Still worth noting though, proper training remains essential for anyone operating these systems. Without adequate knowledge of maintenance routines and day-to-day operation, all those efficiency gains start disappearing fast as breakdowns become more frequent.

Automatic Toilet Paper Rewinder Tissue Paper Manufacturing Machine Reduce Production Cost

The automatic toilet paper rewinder helps cut production costs by taking over what used to be done manually. Instead of workers handling tasks like changing large rolls, trimming edges, and applying glue, this machine does it all automatically. Labor bills drop dramatically while waste materials decrease too. When looking at ROI calculations, the math works out pretty well since operational expenses take a big hit. Many factory owners have already seen results from switching to this system. Some report saving thousands monthly while their production lines run smoother and faster than before. The efficiency gains are impressive enough to make other companies take notice.

Automatic Stabilized Toilet Paper Machine Cutting Machine Manufacturing Toilet Paper Rewinding Machine

Automatic stabilized cutting machines really shine when it comes to flow control tech, something that keeps production lines running steady. Small batch manufacturers especially benefit from this since their orders tend to swing all over the place week to week. These machines handle those ups and downs pretty well, staying reliable even when things get chaotic on the factory floor. Many operators report how these cutters hold up during sudden rush orders too. One plant manager mentioned they handled triple their normal output last quarter without missing a beat, proving just how tough and flexible these machines actually are.

2024 Newest Technology High Speed 1880mm Toilet Paper Rewinding Machine

The latest high speed toilet paper rewinding machines hitting markets in 2024 are making waves because they simply cannot keep up with demand fast enough. These machines pack serious speed while still maintaining good quality standards, which is exactly what manufacturers need right now. Inside these machines lies some pretty cool tech improvements, including those PLC systems that make everything run smoother than ever before. For businesses looking to crank up production without breaking the bank on labor costs, investing in one of these bad boys pays off big time. Factories across several states already report doubling their output levels since switching over to this newer generation equipment, something that would have seemed impossible just a few years back.

Toilet Paper Cutting Machine High Quality Simple Operation Support Customization

What sets this toilet paper cutting machine apart is how well it handles different product specs and sizes while still delivering precise cuts every time. When compared to older cutting techniques, operators notice a real difference in both the accuracy and overall quality of the finished products. Looking at actual examples from companies using these machines shows just how flexible they can be when adapting to particular manufacturing needs. Some businesses have even modified certain parts to fit their unique workflow, which speaks volumes about the machine's adaptable design and focus on making life easier for users on the factory floor.

Avoiding Common Setup Errors in Tissue Paper Machine Operations

Tension Miscalibration Issues

Getting the tension right on tissue paper machines matters a lot if we want to steer clear of those pesky problems like fluffiness or tearing in the end product. When the tension settings are too slack, the resulting paper tends to feel all airy and lacks proper structure. Go too tight though, and watch out for tears forming or excessive stress building up during processing stages. Regular maintenance checks along with good quality calibration equipment make all the difference here. These instruments actually help match the tension to exactly what kind of paper we're working with, which keeps things consistent across batches and maintains overall quality standards. The connection between machine parameters and the actual material used cannot be overstated either. For instance, certain types of paper stock might need completely different tension settings compared to others just to perform at their best level.

Temperature Control Pitfalls

Controlling temperature during tissue paper production matters a lot when it comes to how fibers bond together in the final product. If temperatures aren't properly managed, the bonding between fibers gets messed up, which means the paper won't pass quality checks. Many manufacturers are now installing better temperature monitoring equipment to keep things running at just the right heat throughout production. These systems let operators tweak temperatures on the fly, which helps produce consistently good quality paper rolls. Some companies in the industry have seen noticeable improvements after upgrading their temperature controls. For instance, one plant noticed fewer rejects after they stabilized their drying oven temperatures. When temperatures stay within optimal ranges, fibers stick together properly, making stronger, softer tissue products that customers actually want to buy.

EN

EN

AR

AR BG

BG HR

HR DA

DA FR

FR DE

DE EL

EL PT

PT RU

RU ES

ES TL

TL ID

ID LV

LV LT

LT SR

SR SK

SK UK

UK VI

VI SQ

SQ GL

GL HU

HU TH

TH FA

FA AF

AF GA

GA HY

HY AZ

AZ KA

KA UR

UR BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KU

KU KY

KY