Automated Quality Control Upgrades for Hygiene Paper Manufacturing

Core Components of Automated Quality Control Systems

Sensor Integration for Real-Time Monitoring

When it comes to automated quality control in manufacturing, sensor integration is pretty much what holds everything together. These little devices keep track of all sorts of stuff during production - things like temperature levels, air moisture content, pressure readings, plus plenty of other factors that matter when making toilet paper. Real time data collection means manufacturers get instant feedback they can act on right away, which helps boost overall efficiency while keeping product standards consistent across batches. Companies report significant reductions in both downtime incidents and running expenses once they start using these monitoring systems regularly. Predictive maintenance becomes feasible too, saving money in the long run. Take temperature monitoring for example. If one of those sensors picks up even a small change outside normal operating ranges, plant managers can jump in quickly and tweak settings before anything goes wrong down the production line.

Machine Vision for Defect Detection

Machine vision plays a big part in finding flaws in hygiene paper goods. The technology uses cameras paired with specialized software to catch problems like rips, wrinkles, or alignment issues that might affect how good the product actually is. Companies see several advantages when they implement these vision systems. For one thing, quality checks become much more consistent across batches. Plus, inspections happen faster than manual checks ever could, which speeds things along in the factory. Factories that have added machine vision to their lines report fewer mistakes overall and better quality control from start to finish. Take toilet paper manufacturing for instance. Many plants now run their rolls past high speed cameras that can pick out even the smallest defects in milliseconds. This means fewer boxes of faulty product make it to store shelves, saving money and keeping customers happy with reliable bathroom essentials.

AI-Powered Process Optimization

When it comes to production lines, AI powered optimization is changing things quite a bit by looking at all sorts of data to find where improvements can be made. The algorithms behind these systems dig through mountains of information collected across different stages of manufacturing, which helps boost how well operations run. For instance, they can spot when too much material gets wasted or when products just aren't meeting quality standards consistently. Speed control and proper resource management become much easier thanks to these smart tools, so even something as mundane as running toilet paper machines becomes smoother without constant adjustments. Some factories report around a 25% improvement after implementing AI solutions, though results vary depending on what exactly needs fixing. What's clear though is that manufacturers gain valuable insight into their processes, allowing them to tweak things here and there until everything runs better together, resulting in fewer defects and lower costs down the road.

By integrating these advanced systems, companies can leverage technology to boost productivity while maintaining high standards of quality.

Key Benefits in Hygiene Paper Production

Enhanced Product Consistency

Quality control systems that automate processes are essential for keeping things consistent when making hygiene papers, so every roll or sheet comes out meeting those exact standards we all expect. These days manufacturers use stuff like computer eyes (machine vision) and super accurate sensors throughout their factories. They watch everything happening on the production line and tweak things as needed without stopping the whole operation. Some factory managers have noticed this kind of setup actually boosts consistency quite a bit maybe around 15% better uniformity according to what they've seen over time. When people know they'll get reliably good products every single time they buy something, that builds trust and keeps them coming back to the same brand again and again. Toilet tissue especially needs this kind of reliability because even small differences in thickness or strength can really impact how well it works for customers who might be shopping between different brands at the store.

Reduction in Material Waste

Getting materials right matters a lot for paper production lines, and automation helps cut down on waste substantially. When machines take over the measuring process, they make fewer mistakes than humans do, which can slash waste by around 30% in some cases, studies suggest. Take Valmet Corporation for instance they've been pushing green initiatives for years now by implementing automated solutions that get the most out of every raw material. Less waste means better environmental outcomes too. Paper mills produce far less pollution when they aren't throwing away so much stuff. Plus, going green isn't just good for the planet it also saves money on materials and makes it easier to meet those ever-changing environmental laws that governments keep throwing at manufacturers these days.

Compliance with Hygiene Standards

Maintaining proper hygiene standards matters a lot when making paper products like tissues and toilet paper. Automated systems help keep things clean by producing consistent quality across batches and keeping tabs on every step of manufacturing. When companies follow these rules, they get into markets where regulations are strict and build trust with customers who want dependable products. Many manufacturers have seen success after installing automated quality checks in their facilities. These tech solutions make it easier to stay within guidelines while giving managers instant feedback through built-in audit trails. This kind of oversight helps ensure that finished goods meet those high hygiene expectations consumers demand nowadays.

Featured Automation Solutions for Tissue Manufacturing

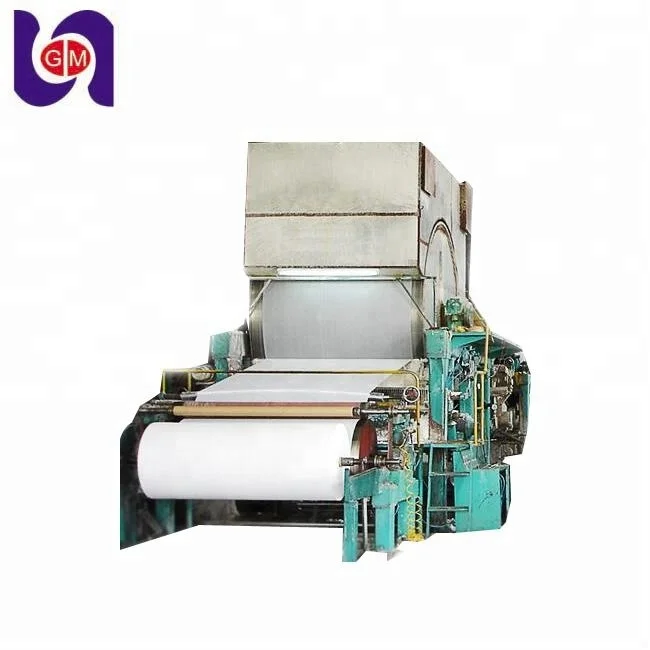

1880mm Tissue Paper Manufacturing System: High-Efficiency Production

The 1880mm tissue paper manufacturing system marks a major advancement for efficient production in the paper industry. Built with cutting edge specs, this setup features a solid PLC control system that automates pretty much everything during production. Compared to older methods, factories report they can crank out way more product while still maintaining good quality standards. What really stands out is how it brings together different automated parts like smart pressure vessels and specialized paper processing tech. These components work together to cut down on manual work and make sure each batch comes out consistent. According to feedback from actual plant managers, companies installing these systems typically see their production times drop by around 30%. This kind of improvement helps businesses keep up with customer demands for premium tissue products without breaking a sweat.

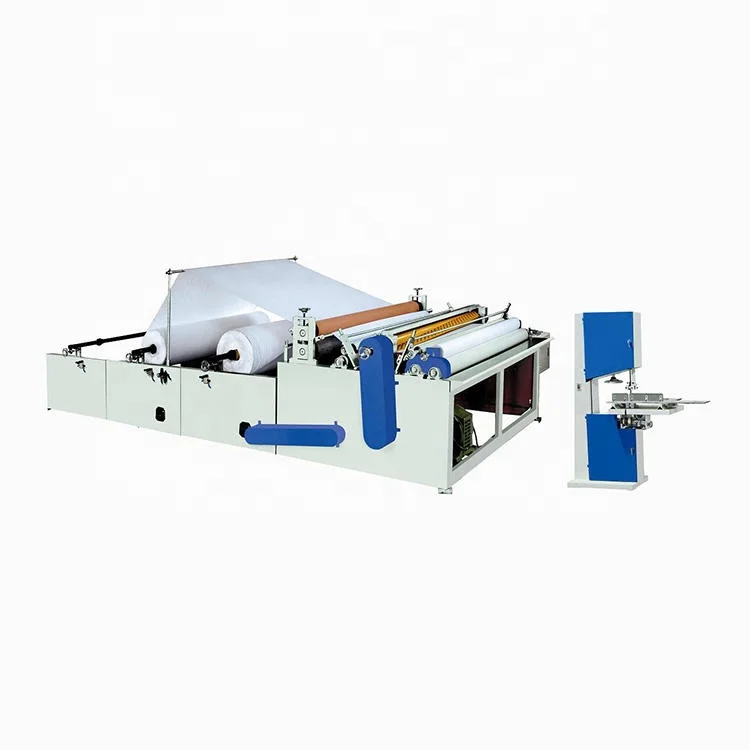

Automatic Toilet Paper Rewinder: Cost-Reduction Technology

The Automatic Toilet Paper Rewinder is changing how tissue producers cut their costs while boosting productivity. Manufacturers can take those huge industrial rolls and break them down into standard sizes without much hassle. The machine comes equipped with things like automatic glue application and accurate cutting mechanisms that make the whole operation run smoother than traditional methods. When companies automate these parts of production, they save money on workers and throw away less product, which means getting their investment back faster. Plants that have switched to this system report dramatic drops in both time spent and cash outlay compared to what they used to spend doing everything by hand. For businesses trying to stay profitable while keeping prices competitive, this kind of tech isn't just helpful anymore it's practically essential in today's market landscape.

Implementation Challenges & Solutions

Adapting Legacy Machinery to Automation

When trying to bring automation into old machinery, businesses run into all sorts of problems. Compatibility is a big one, plus there's the whole cost factor to consider. Most legacy equipment wasn't built with automation technology in mind back when it was manufactured. That makes getting everything to work together pretty tough going sometimes. Money matters too. Companies are stuck between spending on upgrades for what they already own or just buying brand new machines instead. Making this switch happens takes careful planning though. Investing in automated quality checks might seem expensive at first glance, but over time these systems actually boost both efficiency and output across the board. Take Forpak Automation as an example company that managed to retrofit their older production lines with smart sensors and other modern tech without tearing everything down from scratch. Their experience shows real world possibilities for manufacturers dealing with similar situations today.

Training Workforce for Advanced Systems

Moving toward advanced automation in manufacturing means workers need serious training. When staff know how to handle these complicated systems properly, they can prevent costly downtime and mistakes. Many factories now offer detailed training sessions, workshops, and hands-on practice so their teams get comfortable with new tech. The numbers back this up too. Factories that invest in good training see error rates drop dramatically sometimes cutting them in half after just a few months of proper instruction. Take Company X for instance. They rolled out comprehensive training when implementing robots on their assembly line and saw productivity jump while defects dropped significantly. For manufacturers wanting to stay ahead of the curve, smart training programs aren't optional anymore they're essential if plants want to keep pace with competitors who've already made the switch to automated processes.

Future Trends in Paper Manufacturing Automation

IoT Integration for Predictive Maintenance

Bringing IoT into paper manufacturing has changed how companies handle maintenance issues. With IoT systems in place, factories can predict when equipment might fail before it actually happens. This means fewer unexpected shutdowns because sensors monitor everything in real time. The benefit goes beyond just saving time too. Paper machines run better overall and tend to last longer when maintained this way. Cloud computing and machine learning play big roles in making all this work with older factory setups. Looking ahead, most experts think we'll see a lot more paper mills adopting these smart technologies over the coming years. The main reason? Manufacturers want to get more done with less downtime while keeping their operations running smoothly day after day.

Sustainable Production Through Smart Controls

Smart control systems are now playing a key role in making paper manufacturing more sustainable. With these systems, manufacturers can track exactly how much water, energy and raw materials they're using throughout the production process. This kind of detailed oversight cuts down on waste while boosting overall efficiency. When companies integrate automation with intelligent technology, they see real improvements in their environmental impact. For instance, Kimberly-Clark has made major strides by adopting these smart control solutions across several of their facilities. They've managed to maintain output levels while reducing their ecological footprint significantly. Going green isn't just good for the planet anymore either. Businesses that implement these sustainable practices tend to stand out from competitors who haven't caught up yet, giving them an advantage when customers care about where their products come from.

EN

EN

AR

AR BG

BG HR

HR DA

DA FR

FR DE

DE EL

EL PT

PT RU

RU ES

ES TL

TL ID

ID LV

LV LT

LT SR

SR SK

SK UK

UK VI

VI SQ

SQ GL

GL HU

HU TH

TH FA

FA AF

AF GA

GA HY

HY AZ

AZ KA

KA UR

UR BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KU

KU KY

KY